| WONASA Guide: Interpreting the technical characteristics of Natural Stone |

| Time: 2020-09-15 View: 3971 Burst: |

|

Natural stone is one of the most ancient building materials that has accompanied us since our origins. However, strangely, it remains unknown in so many ways to most of us.To know the materials and understand their technical characteristics has become indispensable for the industry since offering this information to all the interested agents will make its use easier. The aim of this Guide is to give technical information on natural stone so as to increase the knowledge of it, the specifications, and use.

一 TECHNICAL CHARACTERISTICS OF STONE TECHNICAL CHARACTERISTICS OF STONE

二 FROM WHERE DO THE NORMS COME WHICH DEFINE THE REQUISITES OF A STONE FOR CONSTRUCTION? The requirements for a stone will depend on the country where the stone is found or the country of its destination. We can find requisites related to the material itself (granite, marble, limestone, etc.) with the construction products (tiles for pavements, slabs for facades, etc.) or the construction system used.

三 HOW DOES ONE KNOW WHAT TESTS NEED TO BE DONE TO THE MATERIALS? It is important to know that, from one country to another, the requisites needed, as also the testing methods may vary by which one arrives at a result. For example, the ASTM norms indicate some minimum values for the type of stone being examined, however, in the majority of the European countries there is no limit for the materials, but it is regulated as a function of the use that is made of the material. On the other hand, if one is talking of the testing methods, these can also vary from one country to another. As an example, the method for determining the resistance to slippage of a stone is different if done in Spain (the pendulum method) to that in Germany (method of the ramp), to that in USA (method of slider).

四 WHAT IS THE OBLIGATORY CE MARKING IN EUROPE? The CE marking indicates that the manufacturer of the product has assured that the harmonised norms have been met. Till now the CE marking in natural stone is obligatory for kerbstones, pavers and tiles for exterior and interior pavements, slabs for facades, tiles for cladding of floors and walls and pieces for manufacture of brickwork, i.e., ashlar walls and similar things. The manufacturers then need to put in place Control Systems of Production, do initial testing on the products and, with certain frequency, new control tests. The results of the tests obtained are embodied in two documents: a declaration of Capabilities and the CE marking is put on the products.

五 AS A PRODUCER, WHAT DOES ONE HAVE TO GIVE TO THE CLIENTS? If one is selling within the EU, one needs to give a Declaration of Capabilities of ones products. In other countries one needs to follow the norms that can have effect but, in all cases, it is important to understand that it is always necessary to do testing frequently of the stone materials and this must be available in the form of ' technical characteristics' with at least the most important test results

六 WHAT ARE THE CHARACTERISTICS CURRENTLY CONSIDERED MOST IMPORTANT? In any techcnical data of a stone it is recommended there be information on some of the following tests: resistance to flexion, resistence to compression, water absorption, density and porosity. There are other important tests but that would depend on the application being made of the stone, which could be tests on slippage, or wearing out in a pavement, or tests of resistance to ice in cold climates. We now deal with the tests that represent the most important characteristics so as to understand their usefulness.

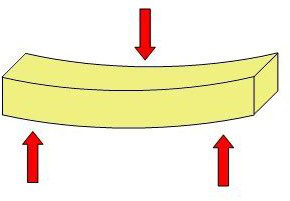

Analysis of important characteristics of stone 1 Resistance to Flexion Let us say that flexion is the deformation that can take place in any element in the perpendicular direction to its longitud axis. This type of stress is undergone by tiles or slabs on the facades. The test is done with a press that keeps increasing the load on the material till its breakage.

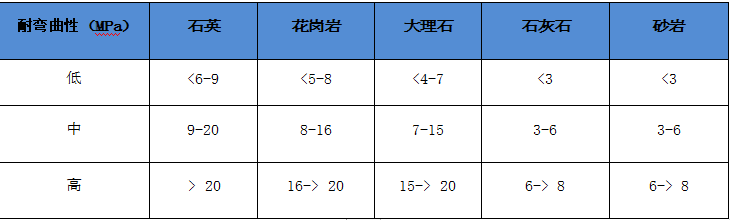

Knowing the value of resistance to flexion is fundamental. A number for resistance of a stone by itself does not indicate that the material is 'better or worse' for a particular application, but one needs to adequately calculate the dimensions. In natural stone, the values of resistance to flexion can vary very much from one material to another. For example, some limestones or sandstones can give values from 2 to 3 Megapascals (MPa) and, on the other hand, slates can give values that can go up to as much as 60 MPa, or more. The following table portrays orientative values of resistance to flexion for different types of stones:

2 Resistance to compression The compression load represents the flattening load, for this the testing is important for stone products that are installed in a big way such as cobblestones or ashlars for walls. The testing is done with a press subjected to loads that flatten it.

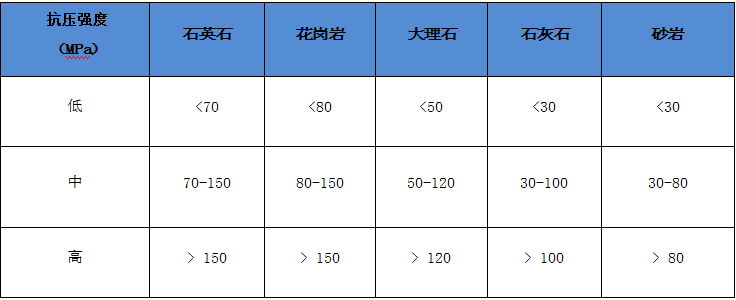

As orientation, the following table portrays the values of resistance to compression for different types of stones.

3 Water absortion The capacity of water absorption of a stone is specially important for some applications. The values of atmospheric water absorption of natural stone can range from almost zero, close to 0% in some marbles and granites, to values of 10% or more for not very dense limestones. The table below shows some common and orientative values

4 Density The density of stone is measured in kgs per cubic metre of material. Greater the density, less is the percentage of porosity and greater the strength and, normally, less capacity of absorption. Within each variety of rock there can be more or less dense stones, even so one can provide, as an example, the following table of values:

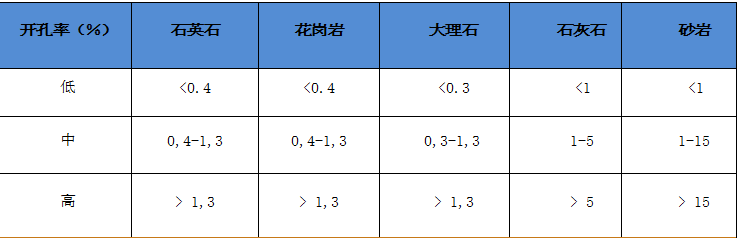

5Porosity The porosity is closely linked to density: more the pores, less dense is the material, i.e., less weight per unit volume. The porosity is given in percentage, and can vary a lot from one material to another, from less than 1% till much higher values for very porous stones such as limestones, travertines and similar.

6 Resistance to wearing out Wearing out has to do with the traffic over the surface of a tile or pavement. There are several ways of measuring the wearing out. The American method gives a result in the form of an index ((Iw), other methods provide a result in milimetres. It is an important characteristic to determine when dealing, for example, with pavements with very high traffic such as shopping centres, train stations, airports, etc. 7 Resistance to slippage It is the capacity of a stone to resist the slippage of a person due to the surface. There are several ways of measuring though the most commonly used is the pendulum of friction, of which one can see the image below: The great advantage of this method is one can do testing at site, i.e., out of the laboratory. Other methods, such as the German, that of the ramp, or that used in USA, BOT 3000, also result useful to determine this characteristic. Depending on the country of destination one can observe the requirements. In a general way, in Europe, the values of slippage greater than 35 are considered safe against slipping. If, on the contrary, one measures with the German method, one will determine the type of slipperiness( from R9 to R13). In USA, on the contrary, one measures the coefficient of dynamic friction, with results between 0 and 1.

Source:LITOS,the Natural Stone Industry Magazine of the World,The copyright belongs to the original author. About the autor: Mrs. Eva Portas Fernández is a technical architect and has developed her professional career for more than 15 years in the natural stone industry. She has been Director of Quality in the testing laboratory of the Technological Centre of Granite in Porriño (Spain). Since 2018 she has been an independent consultan (STEINN)t, working on projects of special relevance and with different public sector and private institutions. Acknowledegements: Thanks to Mr Reiner Krug of the German Stone Association (DNV) for his inputs. |